Watch Live

Metal AMS is the first French Scientific Symposium 100% dedicated to the Metal Additive Manufacturing technologies. Organized by the French Metal AM community in collaboration with major R&D players from around the world, it addresses every step of the AM value chain.

The selected topics concern the areas of expertise including: Design, Materials, Simulation, direct and sintered-base Processes, Monitoring and Control/Qualification challenges.The second edition will be focus on Environement and Sustainable Development.

Scientific and organising Committee 2024: Emmanuel Dunouvion (Aerospace Valley), Nicolas Saintier (Addim Alliance & GIS HEAD), Eric Charkaluk (GIS HEAD & CNRS), Eric Hug (CNRS), Jean-Jacques Blandin (Initiative 3D), Franck Simon (CIMES), Benoit Verquin (Cetim).

Event in partnership with Southern Europe

Download useful document:

Wednesday

March 20th

08:30 - 09:00 / GMT -1 Paris / Opening Statement - Room 6

Replay

09:00 - 09:30 /

GMT -1 Paris / Plenary Session - Room 6

3 - Microstructure control during wire and arc additive manufacturing

João Pedro Oliveira

| Replay

09:30 - 10:00 /

GMT -1 Paris / Plenary Session - Room 6

75 - Ultrastrong nanotwinned titanium alloys through additive manufacturing

Aijun Huang

Monash Centre for Additive Manufacturing, Monash University, Melbourne, Australia

| Replay

10:00 - 10:30 /

GMT -1 Paris / Plenary Session - Room 6

7 - Process Modelling and Uncertainty Quantification in Laser-based Powder Bed Fusion of Metals

Massimo Carraturo

University of Pavia, Pavia, Italy

| Replay

10:30 - 11:15 / GMT -1 Paris / Coffee Break

Room 6

11:15 - 12:35 GMT -1 Paris

S02-1 Process monitoring and NDT Chairmen: Christophe Grosjean / Vincent Bonnefoy

| 13 - Process monitoring and simplified FE modeling of LPBF melt-pools. Influence on the microstructures and mechanical properties of small Inconel 625 struts.

Patrice Peyre

PIMM, UMR 806 CNRS-Cnam-Arts et Métiers, Paris, France

|

9 - Powder Bed Absorptivity in LPBF Additive Manufacturing: Exploring the Interplay of Powder Characteristics, Recoating parameters and Substrate Effects

Robin Kromer

I2M, UMR 5295, Univ. de Bordeaux, Arts et Métiers, CNRS, Talence, France

|

31 - Sinogram-based data augmentation to automate the non-destructive control of mechanical parts

Nina Lassalle-Astis

CETIM Sud-Ouest, Pau, France / LaBRI, Talence, France

|

65 - Review on in-situ thermal monitoring during direct energy deposition: methods, principles and applications

Marcia Meireles

ArcelorMittal, Montataire, France

| Replay

Room 7

11:15 - 12:35 GMT -1 Paris

S03-1 Materials & characterization

Chairmen: Eric Charkaluk / Giorgio De Pasquale

46 - Influence of defect shape and position on the High Cycle Fatigue behaviour of additively manufactured Ti-6Al-4V alloy

Matthieu Bonneric

Arts et Métiers Institute of Technology, Talence, France

|

49 - Fatigue life assessment of WAAM ER70S-6 steel

Ivanna Pivdiablyk

CETIM-Matcor Technology & Service Pte Ltd, Singapore, Singapore

|

62 - Numerical investigation of the influence of defects on the multiaxial fatigue strength of additively manufactured alloys

Sai Sreenivas Penkulinti

I2M Bordeaux, ENSAM, Bordeaux, France

|

28 - Numerical study of first cyclic loadings on additively manufactured 316L stainless steel using a compartmentalized finite element model

Axel Monnier

PhD student in SYMME Laboratory

| Replay

Room 8

11:15 - 12:35 GMT -1 Paris

S04-1 Digital process chain & simulation

Chairmen: Xavier Lorang / Didier Boisselier

38- Numerical simulation of WLAM process for Metal Forming Tool Repair

Yabo Jia

UPHF-LAMIH, 59300, France

|

30 - APPLICATION OF THERMOMECHANICAL MODEL FOR DED PROCESS SIMULATION

Vaibhav Nain

IREPA LASER, Illkirch-Graffenstaden, France

|

67 - NUMERICAL MODEL FOR THE LASER METAL DEPOSITION ADDITIVE MANUFACTURING PROCESS: MULTI-SCALE APPROACH AND EXPERIMENTAL VALIDATION

Ghassen Dali

UTC, Compiegne, France

|

33 - Speeding up mesoscale conduction-based simulations of additive manufacturing processes: focus on temporal discretization and spatial adaptivity.

Simon Essongue

Université de Bordeaux, Talence, France / Institut de mécanique et d'ingénierie - I2M, Talence, France

| Replay

12:35 - 14:00 / GMT -1 Paris / Lunch

14:00 - 14:30 /

GMT -1 Paris / Plenary Session - Room 6

44 - Strategies for Qualification of Parts Printed by Metal Additive Manufacturing with Review of Fatigue Testing Requirements

John H. L. Pang

Nanyang Technological University (NTU), Singapore, Singapore

| Replay

14:30 - 15:00 /

GMT -1 Paris / Plenary Session - Room 6

74 - Effects of heat treatment on the microstructure and mechanical performance of an additively manufactured AlSi7Mg alloy

Gwenaelle Proust

The University of Sydney, Sydney, Australia

| Replay

15:00 - 15:30 /

GMT -1 Paris / Plenary Session - Room 6

1 - Revealing the complexity of 3D printed microstructures of steels

Francisca Garcia Caballero

CENIM-CSIC, Madrid, Spain

|

15:30 - 16:00 /

GMT -1 Paris / Plenary Session - Room 6

70 - Designing fatigue-resistant Additively-Manufactured components: from understanding damage mechanisms in common metallic alloys to establishing a reliable fatigue assessment methodology

Luca Patriarca

Politecnico di Milano, Milano, Italy

| Replay

16:00 - 16:40 / GMT -1 Paris / Coffee Break

Room 6

16:40 - 18:40 GMT -1 Paris

S05-1 Process / DED

Chairmen: David Plélan / John H. L. Pang

68 - XXL Metal Additive Manufacturing : technological challenges and opportunities.

Didier Boisselier

IREPA LASER, ILLKIRCH, France

|

57- Assessment of Wire Arc Additive Manufacturing (WAAM) Techniques through Metallurgical and Mechanical Characterisation in Mild Carbon Steel

Aishwarya

Monash Centre for Additive Manufacturing, Monash University, Melbourne, Australia

|

24 - Maturity, characterisation and decision support system: a multidisciplinary approach to select WAAM-CMT process parameters

Julie Lartigau

Univ. Bordeaux, ESTIA-Institute of Technology, Bidart, France

|

5 - Digital process chains for powder and wire-based 3D DED processes

Rainer Beccard

LUNOVU GmbH, Aachen, Germany

|

59 - Optimization of WLAM process Parameters for Metal Forming Tool Repair

Hans Boungomba

Université Polytechnique des Hauts-de-France - LAMIH - UMR CNRS 8201 Campus Mont Houy, 59313 Valenciennes, France

|

63 - Residual Stress in Wire Arc Additive Manufacturing: Modeling – Instrumentation – Traceability

Elia Zgheib

Société VLM Robotics, Lacanau de Mios, France / Laboratoire Génie de Production, INP-ENIT, Tarbes, France

| Replay

Room 7

16:40 - 18:40 GMT -1 Paris

S06-1 Process / AM sinter-based

Chairmen: Christophe Reynaud / Iñgio Agote

52- Mastering binder-powder interaction using Metal Binder Jetting process parameters for improved green parts quality

Thomas Cheny

MINES Paris, Paris, France

|

34 - Effect of the debinding/sintering strategy on the densification of aluminium alloys processed through Material Extrusion (MEX) Additive Manufacturing

Marion Coffigniez

Université Grenoble Alpes, Saint-Martin d'Hères, France

|

37 - Experimental study on the mechanical post-treatments applied on 17-4PH stainless steel additively manufactured parts.

Mahmoud Naim

Université de technologie de Troyes (UTT), Troyes, France / Ecole polytechnique féminine (EPF), Troyes, France

|

47 - Development of an economical sintering strategy for 316L stainless steel parts printed by Material Extrusion Addive Manufacturing (MEAM)

Sophie Badin

CRITT - Matériaux Innovation, Charleville - Mézières, France

|

22 - Composite Ti-6Al-4V/Polymers Pellets Additive Manufacturing: improvement of the printing parameters to obtain dense and defectless part

Julien Bossu

University of Mons, Mons, Belgium

|

61 - Influence of the layer thickness and contours on mechanical properties of 17-4PH obtained by metal extrusion additive manufacturing

Joseph Marae Djouda

EPF Ecole d'ingénieurs, Cachan, France / Laboratoire de Mécanique de Paris-Saclay, Gif-sur-Yvette, France

| Replay

Room 8

16:40 - 18:40 GMT -1 Paris

S04-2 Digital process chain & simulation

Chairmen: Patrice Peyre / Socona Traoré

32 - Optimizing Velocity and Accuracy in Robotic 3D Printing: Impact of Point Density and Interpolation Methods

Sami Fadil

ADAXIS, Bayonne, France

|

55 - Ertay Material Data Analytics in Nikon SLM Solutions

Deniz Sera Ertay

Nikon SLM Solutions, Lübeck, Germany

|

81 - Novel Multi-Scale Additive Manufacturing PBF Process Simulation Approach for Location-Specific Defect Predictions within Full-Scale Geometries

Simon Poly

|

14 - QuadWire: an extended 1D model for efficient mechanical simulations of bead-based additive manufacturing processes – optimization use case

Laurane Preumont

LMS, CNRS, École Polytechnique, Institut Polytechnique de Paris, Palaiseau, France

|

25 - A thermal-metallurgical-mechanical analysis and hot cracking characterization of grain structure generation via laser powder bed fusion

Zixuan Li

Mine Paris, Sophia Antipolis, France

|

60 - Numerical study of vapor generation on LPBF process - effect on process stability

Morgan Dal

| Replay

18:40 - / GMT -1 Paris / End of Conferences

Thursday

March 21th

08:30 - 09:00 /

GMT -1 Paris / Plenary Session - Room 6

2 - Additive manufacturing of commercial Fe-based metallic glasses for soft magnetic applications

Maria Teresa Perez-Prado

Imdea Materials Institute, Madrid, Spain

| Replay

09:00 - 09:30 /

GMT -1 Paris / Plenary Session - Room 6

42 - Characterization of stainless steel produced by Binder Jetting and qualification process for applications in Oil & Gas industries

Tommaso Tirelli

Aidro - Desktop Metal Company, Taino (Varese), Italy

| Replay

09:30 - 10:00 /

GMT -1 Paris / Plenary Session - Room 6

72 - Additive manufacturing process optimization for innovative aluminium-carbon fibre reinforced polymer co-cured joints

Giorgio De Pasquale

Politecnico di Torino, Torino, Italy

| Replay10:00 - 10:45 / GMT -1 Paris / Coffee Break

Room 6

10:45 - 12:25 GMT -1 Paris

S07-1 Materials & process

Chairmen: Arnold Mauduit / Jean-Christophe Augé

10 - Tensile properties of AlSi7Mg thin specimens manufactured by laser-powder bed fusion

Charles Bianchetti

ONERA, Châtillon, France

|

21 - Identifying Laser Beam Melting (LBM) process window for thin walls by enriching design of experiments with analytical physical models

Clément Ernould

IRT Saint Exupéry, Toulouse, France

|

26 - Understanding ageing mechanism of Al-based metallic powders: probing grain/grain interactions with Atomic Force Microscopy

Yassine Lakroune

|

29 - High performance aluminium components produced by laser powder bed fusion: fatigue performance of Aheadd© CP1

Jean-Christophe Ehrström

Constellium C-TEC, Voreppe, France

|

36 - Comparative study of gaussian, top-hat and donut laser distribution for powder bed fusion additive manufacturing of AlSi10Mg alloy.

Pierre Hébrard

PIMM Lab - Arts et Métiers, Paris, France

| Replay

Room 7

10:45 - 12:25 GMT -1 Paris

S03-2 Materials & characterization

Chairmen: Matthieu Bonneric / Solange Vivès

16 - Printability of Titanium Alloy Ti64 by Additive Friction Stir Deposition: Study of process-microstructure-macroscopic properties

Ismail Zabeeullah Kolimi

Université de technologie de Compiègne,CNRS, Roberval (Mechanics Energy and Electricity), Compiegne, France

|

19 - Optimization of heat treatments for a LP – DED Maraging 18Ni300 steel to improve mechanical properties.

Hugo Huttenschmitt

MBDA, Bourges, France

|

50 - Predicting powder spreadability for metal AM.

Aurelien Neveu

|

54 - Latest advances in additive manufacturing characterization at European Synchrotron Radiation Facility (ESRF)

Andrea Francesco Ciuffini

ESRF, Grenoble, France

|

69 - Contribution of TEM to the study of metals processed by additive manufacturing

Arthur Despres

Grenoble INP - Laboratoire SIMaP, Grenoble, France

| Replay

Room 8

10:45 - 12:25 GMT -1 Paris

S08-1 Post processing / surface posttreatment

Chairmen: Guillaume Badinier/ Ivanna Pivdiablyk

11 - A new hybrid electrochemical-mechanical process (PEMEC) for polishing additively manufactured parts.

Joël Reich

|

4- super finishing MMP Technology : surface engineering to make your parts perform even better

Frédéric Bajard

Binc Industries, Saint-Priest, France

|

77- Strength/ductility trade-off of Laser Powder Bed Fusion Ti-6Al-4V: synergetic effect of alpha-case formation and microstructure evolution upon heat treatments

Quentin Gaillard

|

8 - Surface finishing technologies adapted for 3D printing mechanical components. Multi Process post processing treatment of high value additive manufacturing components

Martin Jay

POLITECHNO, Bonson, France

|

78 - Support-free DMLS® printing: myth or reality?

André Surel

| Replay 12:25 - 13:50 / GMT -1 Paris / Lunch

13:50 - 14:20 /

GMT -1 Paris / Plenary Session - Room 6

64 - Laser-powder bed fusion of high strength AlFeCrX aluminium alloys

Carmen Cepeda-Jimenez

National Center for Metallurgical Research (CENIM, CSIC), Madrid, Spain

| Replay

14:20 - 14:50 /

GMT -1 Paris / Plenary Session - Room 6

23 - Binder Jetting process Sustainablity: Powder Managemente

Iñigo Agote

TECNALIA, San Sebastián, Spain

| Replay

14:50 - 15:20 /

GMT -1 Paris / Plenary Session - Room 6

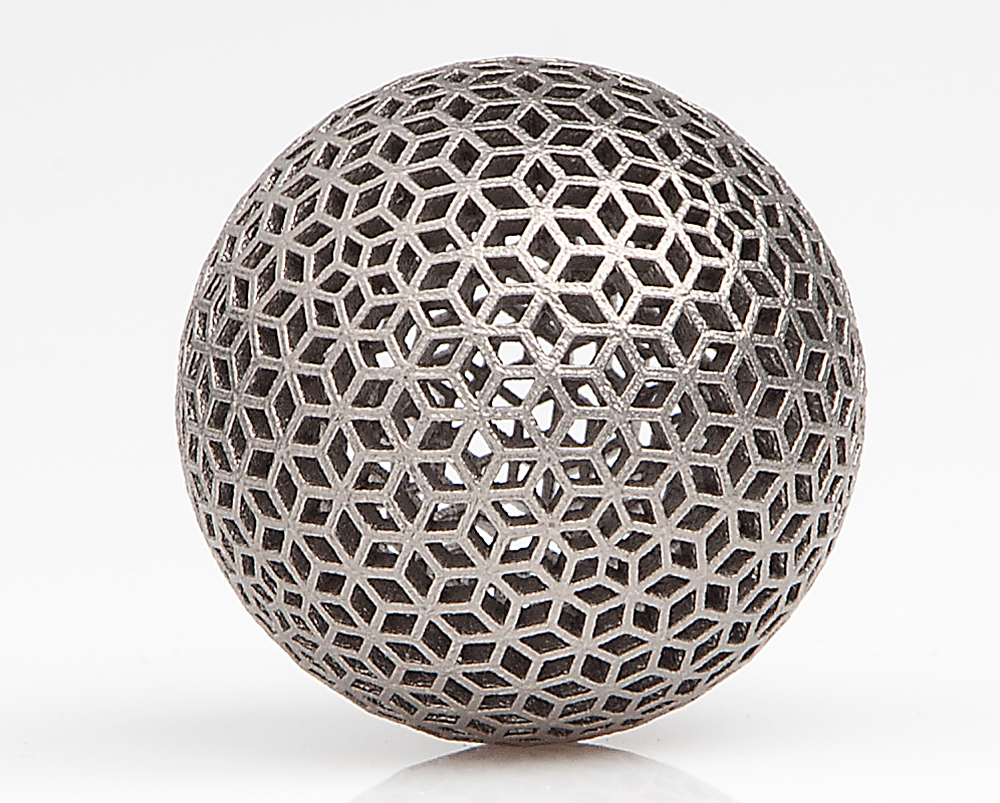

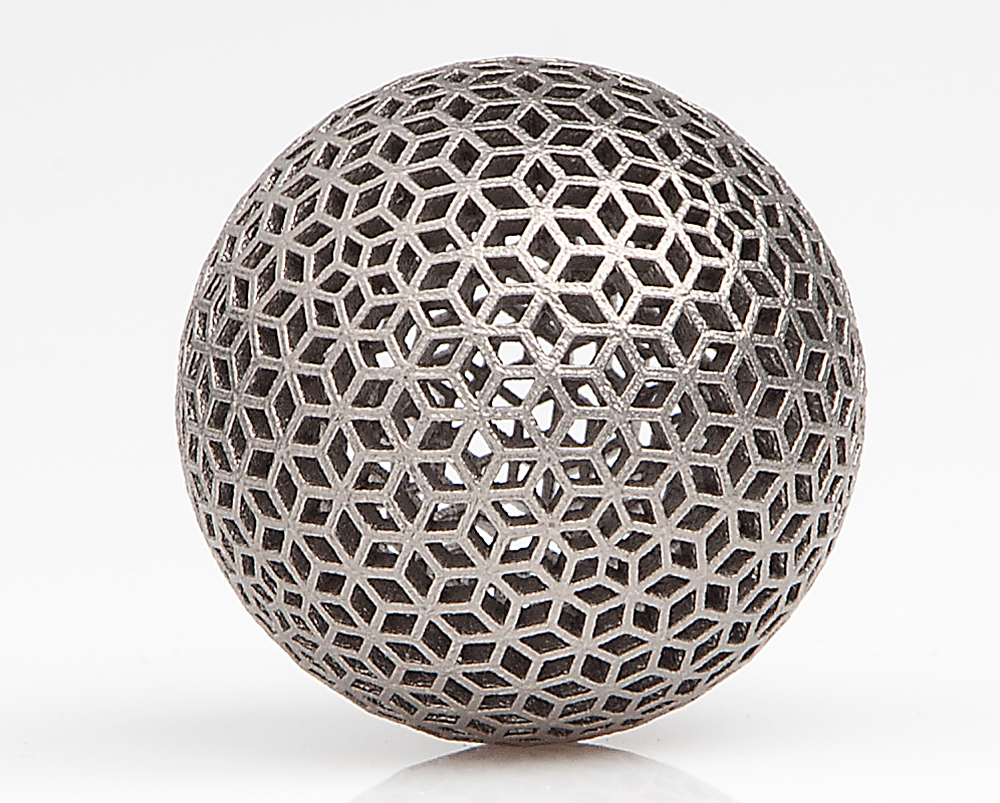

71 - BINDER JETTING ADDITIVE MANUFACTURING FOR JEWELLERY AND FASHION ITEMS PRODUCTION

Andrea Friso

Legor Group S.p.A., Vicenza, Italy

| Replay15:20 - 16:05 / GMT -1 Paris / Coffee Break

Room 6

16:05 - 17:45 GMT -1 Paris

S09-1 Applications and sustainability / process qualification

Chairmen: Nicolas Saintier / Maxime Fayolle

58 - Additive Manufacturing of nuclear Fuel Assembly metallic components - overview of Machine/Process qualification strategy

Guillaume Badinier

Framatome, Lyon, France

|

48 - Additive manufacturing of austenitic stainless steel non-planar and small thickness product by WAAM process

Théo Racine

Naval Group, Indret, France

|

17 - Wire and Arc Additive Manufacturing of Large Safety-CriticalComponents in the Nuclear Industry: Influence of Deposition Rate in the Submerged Arc Process

Antoine Kieffer

EDF R&D, Les Renardières, 77250 Moret sur Loing, France Univ Lyon, INSA Lyon, UCBL, MATEIS, UMR5510, 69621 Villeurbanne, France

|

18 - Laser powder bed fusion process development for copper-aluminium alloys : towards spare parts for the railway infrastructures

Marie Fischer

Pint, Metz, France

|

82 - From R&D to Mass Production with the HP Metal Jet S100 Rocío Muñoz

Rocío Muñoz Moreno

|

Replay

Room 7

16:05 - 17:45 GMT -1 Paris

S10-1 Advanced materials

Chairmen: Fabien Lefebvre / Massimo Carraturo

15 - Microstructure and mechanical properties of as-built and heat-treated Laser Powder Bed Fusion Al0.3CoCrFeNi High Entropy Alloy

Thierry Baffie

CEA-LITEN, Univ.Grenoble Alpes, Grenoble, France

|

66 - New generation of high-performance metal powders designed for AM

Solange Vives

Aubert&Duval, Paris, France

|

56 - Heat exchangers using TPMS architectures manufactured by LPBF

Vincent Bonnefoy

CEA LITEN, Université Grenoble Alpes, Grenoble, France

|

27 - Experimental and numerical evaluation of mechanical properties of hybrid lattice structures manufactured by selective laser melting

Zhaozhen Huang

Univ. Savoie Mont Blanc, SYMME, Annecy, France

|

35 - EFFECT OF AM PROCESSES ON THE COMPRESSIVE BEHAVIOUR OF 316L ARCHITECTED MATERIALS

Camille Buros

Univ. Bordeaux, ESTIA-Institute of technology, BIDART, France

|

Replay

Room 8

16:05 - 17:45 GMT -1 Paris

S07-2 Materials & process

Chairmen: Marc Thomas / Socona Traoré

6 - Study of oxide nanoprecipitate formation mechanisms in 316 L stainless steel produced by rapid solidification processes: gas atomization and Laser Powder Bed Fusion (L-PBF)/ effect on impact toughness.

Salima Benrabah

|

45 - Portevin-Le Chatelier effects in 316L stainless steels processed by LPBF for nuclear applications

Sylvain Dépinoy

Mines Paris Université PSL, MAT - Centre des Matériaux, CNRS UMR 7633, Evry, France

|

51 - Study of strain heterogeneity within the microstructure of an additively manufactured 316L subjected to tensile and fatigue stresses using neutron diffraction and 3DXRD.

Lorène Héraud

I2M, Arts et Métiers Institute of Technology, Talence, France

|

53 - Understanding the macroscopic properties of the PBF-LB 17-4 PH steel by a set of microstructural investigationsliveira Melo

Renata de Oliveira Melo

CNRS, INRAE, Centrale Lille, UMR 8207—UMET—Unité Matériaux et Transformations, Université de Lille, Lille, France

|

73 - Durability of additively manufactured austenitic stainless steels under fatigue-hydrogen coupling

Rahul Subramanian Girija

Institut de Mécanique et d'Ingénierie (I2M) UMR 5295, Bordeaux, France

| Replay

17:45 - 18:00 / GMT -1 Paris / Closing Ceremony - Room 6

Replay